-

Courses

Courses

Choosing a course is one of the most important decisions you'll ever make! View our courses and see what our students and lecturers have to say about the courses you are interested in at the links below.

-

University Life

University Life

Each year more than 4,000 choose University of Galway as their University of choice. Find out what life at University of Galway is all about here.

-

About University of Galway

About University of Galway

Since 1845, University of Galway has been sharing the highest quality teaching and research with Ireland and the world. Find out what makes our University so special – from our distinguished history to the latest news and campus developments.

-

Colleges & Schools

Colleges & Schools

University of Galway has earned international recognition as a research-led university with a commitment to top quality teaching across a range of key areas of expertise.

-

Research & Innovation

Research & Innovation

University of Galway’s vibrant research community take on some of the most pressing challenges of our times.

-

Business & Industry

Guiding Breakthrough Research at University of Galway

We explore and facilitate commercial opportunities for the research community at University of Galway, as well as facilitating industry partnership.

-

Alumni & Friends

Alumni & Friends

There are 128,000 University of Galway alumni worldwide. Stay connected to your alumni community! Join our social networks and update your details online.

-

Community Engagement

Community Engagement

At University of Galway, we believe that the best learning takes place when you apply what you learn in a real world context. That's why many of our courses include work placements or community projects.

BladeComp

BladeComp – a design and optimisation software for wind and tidal turbine blades

Introduction

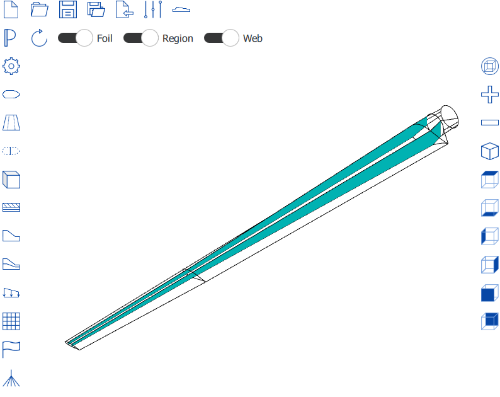

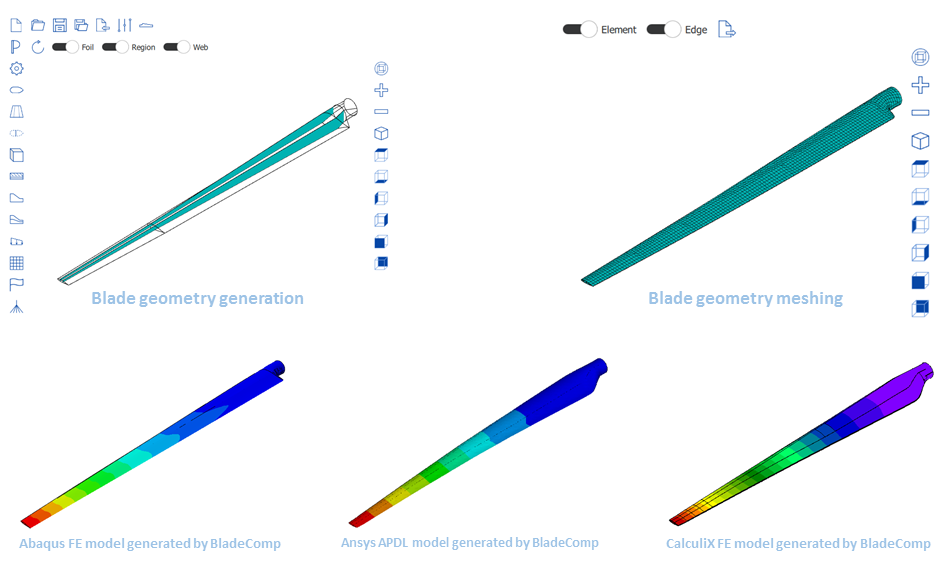

BladeComp is an in-house developed wind/tidal turbine blade design and optimisation software. The BladeComp comprises advanced Finite Element (FE) analysis techniques and design optimisation strategies for efficient, robust and rapid design of turbine blades. The methodology for designing wind/tidal blade is utilized by the BladeComp, which can produce blade model for a range of input properties, such as air-foils, composite materials and layup distributions.

This software has been used to design rotor blades for the 2 MW Orbital Marine Power floating tidal turbine device, which is manufactured in Ireland (Galway) by ÉireComposites and is tested in our facility under static and fatigue loading. The test results validate the reliability of this software. The BladeComp is also used to optimise the structural performance of a 15kw wind turbine blade, where the strength of the optimised blade is significantly improved without increase the blade mass. In the worldwide context, this will put the MaREI Centre at NUI Galway at the forefront of design and testing of full-scale tidal turbine rotor blades, rotor blades, which is necessary to exploit the full potential of marine energy as a significant renewable resource.

Features

- Blade geometry creation

- Composite layers assignment

- Input file generation for FE software, ABAQUS, Ansys APDL and CalculiX

- Structure behaviour Optimisation (under development)

Downloads & Resources

If you get the "missing dll file error", please install the "VC_redist.x64.exe" in the program folder.

Contacts

Dr Yadong Jiang, yadong.jiang@universityofgalway.ie

Dr William Finnegan, william.finnegan@universityofgalway.ie

Prof Jamie Goggins, jamie.goggins@universityofgalway.ie

Publications

| Year | Publication |

|---|---|

| 2024 | Ahmad, A., Munaweera Thanthirige, T.R., Finnegan, W., Jiang, Y., Flanagan, M., Kazemi Vanhari, A. and Goggins, J. (2024), “Evaluating the structural changes during physical testing of a full-scale 13 metre long wind turbine blade”, in Proceeding of the Civil Engineering Research in Ireland 2024, Galway, Ireland, pp. 487–493. [link] |

| 2023 | Jiang, Y., Finnegan, W., Wallace, F., Flanagan, M., Flanagan, T. and Goggins, J. (2023), “Structural analysis of a fibre-reinforced composite blade for a 1 MW tidal turbine rotor under degradation of seawater”, Journal of Ocean Engineering and Marine Energy, Vol. 9, pp. 477–494, doi: 10.1007/s40722-023-00279-w. |

| 2023 | Jiang, Y., Finnegan, W. and Goggins, J. (2023), “Structural performance optimisation of a composite rotor blade for retrofitting a 225-kW wind turbine”, in Oceans 2023, Limerick, Ireland, doi: 10.1109/OCEANSLimerick52467.2023.10244552. |

| 2023 | Jiang, Y., Finnegan, W., Flanagan, T. and Goggins, J. (2023), “Optimisation of Highly Efficient Composite Blades for Retrofitting Existing Wind Turbines”, Energies, Vol. 16 No. 1, p. 102, doi: 10.3390/en16010102. |

| 2022 | Finnegan, W., Jiang, Y., Meier, P., Hung, L.C., Fagan, E., Wallace, F., Glennon, C., et al. (2022), “Numerical modelling, manufacture and structural testing of a full-scale 1 MW tidal turbine blade”, Ocean Engineering, Vol. 266 No. 1, p. 112717, doi: 10.1016/j.oceaneng.2022.112717. |

| 2022 | Jiang, Y., Fagan, E.M., Finnegan, W., Kazemi Vanhari, A., Meier, P., Salawdeh, S., Colm, W., et al. (2022), “Design and Structural Testing of Blades for a 2MW Floating Tidal Energy Conversion Device”, Materials Research Proceedings, Vol. 20, pp. 74–80, doi: 10.21741/9781644901731-10 |

| 2021 | Jiang, Y., Finnegan, W., Wallace, F., Flanagan, M., Flanagan, T. and Goggins, J. (2022), “Numerical Modelling and Structural Analysis of a 1 MW Tidal Turbine Blade”, The 9th Conference on Computational Methods in Marine Engineering (Marine 2021), doi: 10.2218/marine2021.6799. |

| 2021 | Jiang, Y., Finnegan, W., Wallace, F., Flanagan, M., Flanagan, T. and Goggins, J. (2021), “Structural Analysis of a 1 MW Tidal Turbine Blade through Full-Scale Physical Testing and a Digital Twin”, in The Proceedings of the 9th Conference on Computational Methods in Marine Engineering, UK. |

| 2020 | Finnegan, W., Jiang, Y., Dumergue, N., Davies, P. and Goggins, J. (2021), “Investigation and Validation of Numerical Models for Composite Wind Turbine Blades”, Journal of Marine Science and Engineering, Vol. 9 No. 5, p. 525, doi: 10.3390/jmse9050525. |

| 2020 | Finnegan, W., Jiang, Y., Dumergue, N., Davies, P. and Goggins, J. (2021), “Structural testing and FEA dataset for a composite turbine blade”, SEANOE, doi: 10.17882/80564. |

| 2020 | Kazemi Vanhari, A., Fagan, E., Jiang, Y., Meier, P., Finnegan, W. and Goggins, J. (2020), “Equivalent Load Profile Development For Fatigue Testing Of a 13-Metre Wind Turbine Blade”, in Civil Engineering Research in Ireland 2020: Conference Proceedings, Cork, Ireland, pp. 253–258. |

| 2019 | Jiang, Y., Fagan, E.M., Goggins, J., 2019. Structural design and optimisation of a full-scale tidal turbine blade, in: Vicinanza, D. (Ed.), Proceedings of the Thirteenth European Wave and Tidal Energy Conference. Presented at the the Thirteenth European Wave and Tidal Energy Conference, EWTEC, Universitá degli Studi della Campania “Luigi Vanvitelli”, Italy. [link] |

| 2018 | Fagan, E.M., De La Torre, O., Leen, S.B., Goggins, J., 2018. Validation of the multi-objective structural optimisation of a composite wind turbine blade. Compos. Struct. 204, 567–577. [DOI] |

| 2017 | Fagan, E.M., 2017. Design of fibre-reinforced polymer composite blades for wind and tidal turbines (PhD Thesis). National University of Ireland, Galway. [link] |

| 2017 | Fagan, E. M., Flanagan, M., Leen, S.B., Flanagan, T., Doyle, A., Goggins, J., 2017. Physical experimental static testing and structural design optimisation for a composite wind turbine blade. Compos. Struct. 164, 90–103. [DOI] |

| 2017 | Fagan, Edward M., Leen, S.B., Torre, O. de la, Goggins, J., 2017. Experimental investigation, numerical modelling and multi-objective optimisation of composite wind turbine blades. J. Struct. Integr. Maint. 2, 109–119. [DOI] |