-

Courses

Courses

Choosing a course is one of the most important decisions you'll ever make! View our courses and see what our students and lecturers have to say about the courses you are interested in at the links below.

-

University Life

University Life

Each year more than 4,000 choose University of Galway as their University of choice. Find out what life at University of Galway is all about here.

-

About University of Galway

About University of Galway

Since 1845, University of Galway has been sharing the highest quality teaching and research with Ireland and the world. Find out what makes our University so special – from our distinguished history to the latest news and campus developments.

-

Colleges & Schools

Colleges & Schools

University of Galway has earned international recognition as a research-led university with a commitment to top quality teaching across a range of key areas of expertise.

-

Research & Innovation

Research & Innovation

University of Galway’s vibrant research community take on some of the most pressing challenges of our times.

-

Business & Industry

Guiding Breakthrough Research at University of Galway

We explore and facilitate commercial opportunities for the research community at University of Galway, as well as facilitating industry partnership.

-

Alumni & Friends

Alumni & Friends

There are 128,000 University of Galway alumni worldwide. Stay connected to your alumni community! Join our social networks and update your details online.

-

Community Engagement

Community Engagement

At University of Galway, we believe that the best learning takes place when you apply what you learn in a real world context. That's why many of our courses include work placements or community projects.

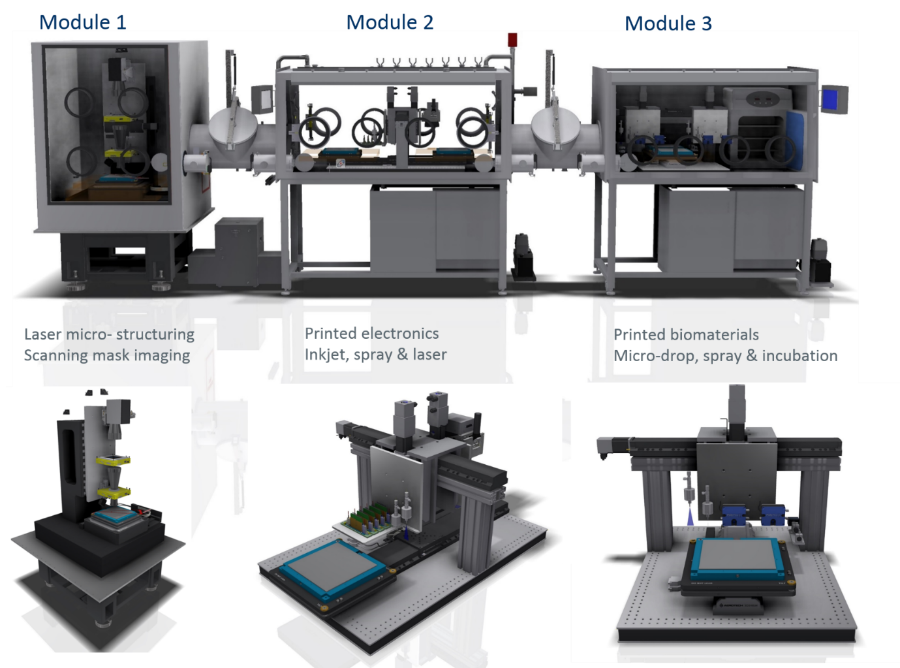

Pilot Line for Bio-Microsystems

Additive and subtractive manufacturing testbed for creating next generation electrically, optically and thermally – activated biomaterials

The NCLA Laser Laboratory in partnership with SFI centres CURÁM Medical Devices, IPIC Irish Photonics Integration Centre and I-Form Advance Manufacturing is developing a new pilot manufacturing test-bed for next generation medical devices.

The system will demonstrate the manufacturability of new technologies at the interface of printed electronics and bioprinting.

The system consists of three connected sealed modules. A laser based micro-structuring module will create structured surfaces for microfluidics and embedded electronics. A dry materials additive module will use inkjet and spray tools to create structured conductive/ non-conductive surfaces. A bioprinting module will apply living cells and other life-supporting biomaterials. The ability to integrate electronic, optical, and thermal stimuli in flexible medical devices will be transformative –changing the way we connect with, and use, future healthcare products

Download Information here: Pilot Line Flyer

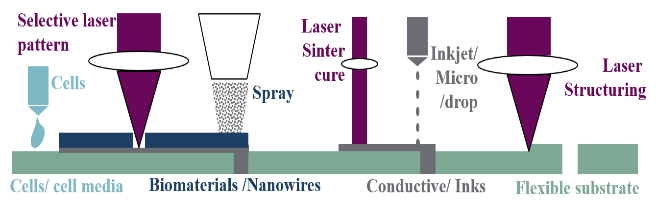

Laser enabled multi-materials manufacturing

While the infrastructure addresses future biomedical needs, the scope is firmly centred on materials processing. Every aspect of the project exploits the huge potential for short and ultra-short pulsed laser matter interactions. The challenge is to transform drop-based printing of multiple electronic- and bio-materials using pre- and post- laser processes.

- Advanced laser processes will be used to structure microfluidics, to create landing sites for electronic die and flexible batteries, and to drill crack free via holes through thin brittle substrates.

- Laser processes will structure surfaces prior to and after drop based printing by inkjet or spray. Pre-processing by laser will improve drop surface interactions, post processes will sinter or cure.

- Conversely selective laser patterning of thin films and surfaces can be promptly filled with drop-based electronic or bio-inks, and subsequent sintered and cured in the same process scan.

Laser and Drop-based Printing Technologies

The infrastructure exploits the interplay between laser and drop based printing technologies, to produce electronically activated biomaterials on a high volume manufacturing platform compatible with roll to roll, sheet to sheet and cylindrical manufacturing systems.

|

|

|

Acknowledgements

This project has received funding from the Science Foundation Ireland’s Infrastructure call in 2016 under contract 16/RI/3761.

| |  |

|

|

|

|